Building a Proactive Support Strategy Using Predictive Analytics and IoT Data

Let’s be honest. Most customer support feels like an ambulance at the bottom of a cliff. The problem happens, the alarm sounds, and you scramble to react. It’s stressful, expensive, and frankly, it leaves everyone—you and your customer—feeling a bit bruised.

But what if you could see the cracks in the cliff face before anyone falls? That’s the promise of shifting from reactive to proactive support. And the tools to build that foresight? They’re already here, in the marriage of predictive analytics and the rivers of real-time information flowing from IoT data.

From Firefighting to Forecasting: The Core Mindset Shift

Proactive support isn’t just faster support. It’s a different species altogether. The goal is to prevent the issue entirely, or at the very least, to have the solution already in motion before the customer even knows there’s a problem.

Think of it like maintaining a car. Reactive support is waiting for the engine to seize. Proactive support is the check-engine light—or better yet, the mechanic’s software that reads data from your car and emails you to say, “Your battery health is at 15%, let’s schedule a replacement next Tuesday.” That’s the shift. And IoT sensors are your eyes and ears inside the product, while predictive analytics is the brain making sense of it all.

How IoT Data Fuels the Foresight Engine

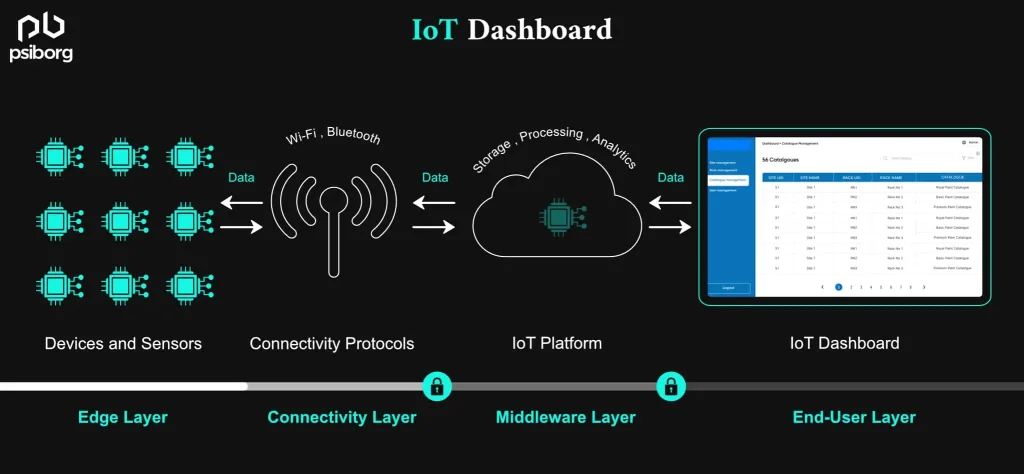

Internet of Things (IoT) devices are, at their core, chatterboxes. They constantly report on their own condition. Temperature, vibration, pressure, usage cycles, error codes, power fluctuations… you name it. This isn’t just “big data”; it’s high-resolution, real-time operational data straight from the source.

For a complex piece of industrial machinery, that might mean 10,000 data points per second. For a smart home appliance, it might be a daily digest of motor performance and cycle counts. This data is the essential fuel. Without it, any predictive model is just guessing.

Where Predictive Analytics Comes Into Play

Here’s where it gets interesting. All that IoT data on its own is just noise—a chaotic symphony of numbers. Predictive analytics is the conductor. It uses machine learning algorithms to find patterns in historical and current data, identifying the precise signatures that precede a failure.

For instance, the model might learn that in 95% of past failures, a specific sequence occurred: a gradual increase in motor vibration (by 12%) followed by three minor thermal spikes within 48 hours. When it sees that exact pattern emerging in a currently deployed unit, it can flag it. Not as a failure, but as a high-probability precursor to one.

The Practical Blueprint: Turning Insight into Action

Okay, so you have the data and the brains. How do you actually build this? It’s less about a single magic tool and more about connecting stages in a workflow.

- Stage 1: Instrumentation & Data Aggregation. First, your products need to be sensor-equipped and connected. The data must flow reliably into a centralized platform—a data lake or cloud warehouse. This is the non-negotiable foundation.

- Stage 2: Model Development & Training. Here, data scientists (or increasingly, accessible AI platforms) build models using your historical failure data. They ask: “What did the data look like in the days before things went wrong?”

- Stage 3: Integration & Alerting. The predictive model needs to be plugged into your operational systems. When it flags an anomaly, it shouldn’t just create a report. It should automatically generate a ticket in your CRM or service desk platform, tagged with the predicted issue, probability score, and recommended action.

- Stage 4: The Human-in-the-Loop Action. This is where your support strategy truly comes alive. The alert prompts a defined proactive intervention.

What Proactive Intervention Actually Looks Like

This is the “so what?” moment. That automated ticket triggers a real-world response. Here are a few powerful examples:

| Industry | Predictive Signal (from IoT + Analytics) | Proactive Support Action |

| HVAC Systems | Compressor efficiency dropping, correlated with rising outdoor temps. | Dispatch a technician for pre-summer maintenance; send customer a scheduling link with a note about optimizing cooling efficiency. |

| Fleet Management | Brake pad sensor data shows unusual wear pattern on a specific vehicle. | Automatically schedule the truck for service at its next planned depot stop; parts are ordered ahead of time. |

| Medical Imaging Devices | Subtle deviations in calibration data, trending slowly over months. | Remote diagnostic check confirms; a service engineer is sent with the correct calibration kit before image quality is affected. |

See the pattern? The support team transitions from a call center to a mission control center. They’re not waiting for the distress signal; they’re monitoring vital signs and deploying resources with precision.

The Tangible Benefits—Beyond Just Happy Customers

Sure, customer satisfaction and loyalty skyrocket. That’s a given. But the operational wins are just as compelling. You can drastically reduce high-cost, emergency field service visits. Inventory management improves because you can predict which parts will be needed, and where. You extend the lifespan of your assets. And you unlock a powerful new revenue stream: selling uptime itself through service-level agreements (SLAs) with guaranteed, data-backed reliability.

Honest Challenges and How to Sidestep Them

It’s not all smooth sailing, of course. Data quality is everything—garbage in, garbage out. You’ll need to navigate data privacy concerns, especially with consumer IoT. And building trust is key; you have to be right more often than not, or customers will start to see your “proactive” alerts as just clever marketing.

Start small. Pick a single, high-impact product line or a common, costly failure mode. Build a pilot. Use the results to win internal buy-in and refine your process. The goal isn’t perfection out of the gate; it’s learning and demonstrating value.

The Future Is Proactive (And It’s Already Here)

In the end, building a proactive support strategy with predictive analytics and IoT data is about respect. It respects the customer’s time and business continuity. It respects your own operational efficiency. And it respects the intelligence embedded in your products, finally giving them a true voice.

The technology is ready. The data is there, whispering what it knows. The question isn’t really if this is the future of support—it’s how quickly we choose to listen.