Building a Hyper-Local Supply Chain: Your Blueprint for Resilient Retail & Manufacturing

Let’s be honest. The last few years have been a masterclass in supply chain fragility. A ship gets stuck in a canal, and suddenly your inventory is stuck in the middle of the ocean. A factory on the other side of the world shuts down, and your production line grinds to a halt. It’s enough to make any business owner or operations manager want to pull their hair out.

That’s where the hyper-local supply chain comes in. It’s not just a buzzword; it’s a fundamental shift in thinking. Instead of stretching your operations across continents, you build a network of suppliers, producers, and partners within a tight geographic radius—think 50, 100, maybe 200 miles. It’s about creating an ecosystem, not just a logistics line.

And the benefits? They go way beyond just avoiding the next port congestion. We’re talking about radical transparency, a smaller carbon footprint, and a level of community connection that global giants simply can’t replicate. Here’s the deal on how to build one.

Why Go Hyper-Local? The Compelling Case

Sure, sourcing from a low-cost country might look good on a spreadsheet. But hidden costs lurk everywhere: shipping delays, quality miscommunications, and a total lack of visibility. A hyper-local supply chain flips the script.

Resilience is the New Efficiency

When your key supplier is a short drive away, you can react. Fast. A last-minute design change? You can visit the workshop in person. A sudden spike in demand? You can coordinate a quicker turnaround. This agility is a superpower in today’s market. It turns your supply chain from a liability into a genuine competitive advantage.

The Sustainability & Storytelling Bonus

Consumers, honestly, are smarter than ever. They want to know the story behind their products. “Locally sourced” isn’t just a tagline; it’s a promise of lower transportation emissions, support for the regional economy, and often, higher quality. For manufacturing, this means a stronger ESG (Environmental, Social, and Governance) profile without the greenwashing. It’s a real, tangible benefit you can market.

Mapping Your Hyper-Local Network: A Practical Guide

Okay, so you’re convinced. But where do you start? You can’t just snap your fingers and have a network appear. It requires a bit of detective work and a shift in how you view your own backyard.

Step 1: The Local Supplier Audit

Begin with what you already use. Audit your current bill of materials or product components. For each item, ask: “Could this be made, grown, or assembled closer to home?” You’d be surprised. There might be a small-batch ceramics studio that could make your packaging inserts, or a family-owned metal shop with CNC capabilities down the road.

Tools like local industry directories, regional manufacturing hubs, and even platforms like LinkedIn (search by location!) are goldmines. Don’t forget old-school networking—chamber of commerce meetings are suddenly relevant again.

Step 2: Rethink Inventory & Storage

Hyper-local doesn’t always mean holding massive stock. In fact, it can enable a shift towards on-demand production or micro-fulfillment. Imagine small batch manufacturing runs that feed directly into local retail stores, bypassing centralized warehouses entirely.

This might mean using distributed micro-warehouses—perhaps a shared space in an industrial park—to hold inventory much closer to your end customer. The goal is to shorten that last mile until it’s practically a last lap.

Step 3: Forge Real Partnerships

The Tech That Makes It Possible

This isn’t a return to the 1950s. Modern hyper-local chains are powered by smart technology. You’ll need:

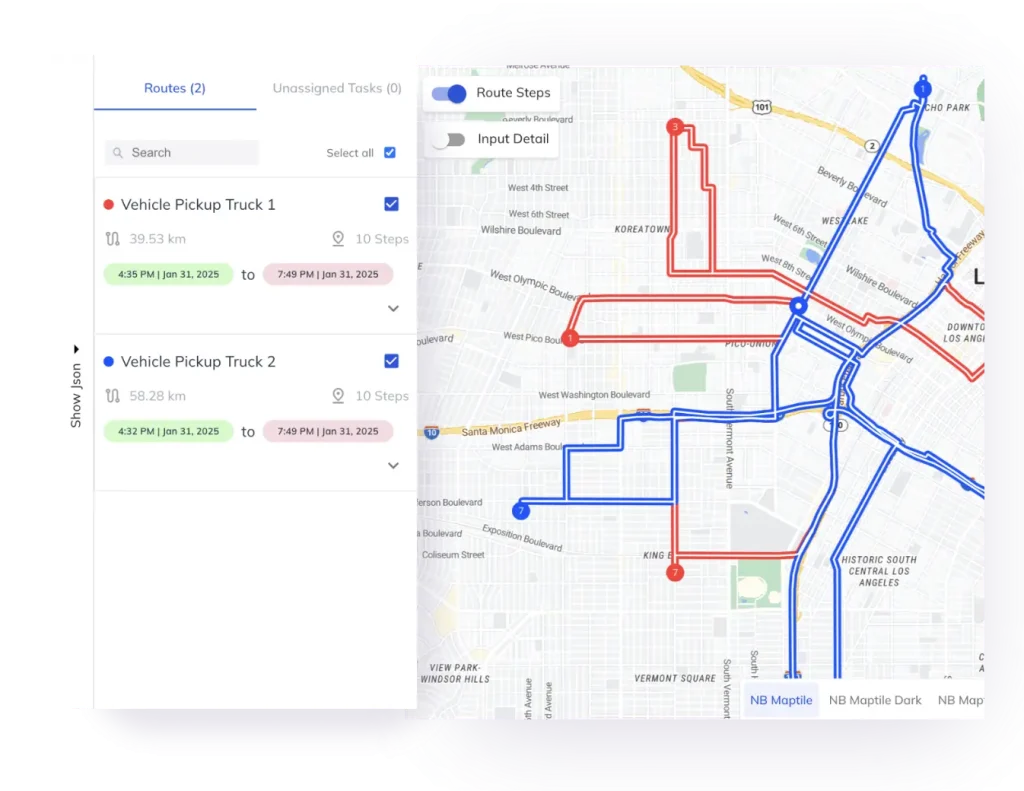

- Cloud-Based Collaboration Platforms: Shared dashboards where your local fabricator, assembler, and you can see real-time order status, not buried in email chains.

- IoT for Visibility: Simple sensors can tell you when raw materials arrive at a partner’s facility or when a batch is complete.

- Localized Logistics Apps: Platforms that connect you with same-day local couriers or independent truckers for those short-haul moves.

The tech acts as the nervous system, connecting all the independent parts of your local ecosystem.

Navigating the Real-World Challenges

It’s not all sunshine and local roses. You’ll face hurdles. Cost is the big one—local labor and materials often come at a premium. The solution? You have to reframe the value. Factor in the savings from reduced shipping insurance, lower inventory holding costs, and the avoided losses from disruptions. The math starts to look different.

Another challenge is scale. A local artisan might not be able to handle a 10,000-unit order. This is where your network design is key. Maybe you work with several small workshops in parallel, or you help a key partner invest in scaling their capacity. You grow together.

| Challenge | Hyper-Local Solution Mindset |

| Higher Unit Cost | Value resilience, speed, quality, and marketing appeal. Calculate Total Cost of Ownership, not just unit price. |

| Limited Scale | Design products for local manufacture. Use multiple micro-suppliers. Plan for phased growth with partners. |

| Finding Partners | Invest time in community engagement. Attend trade shows, use local B2B directories, ask for referrals. |

| Coordination Complexity | Implement shared cloud software (like simple ERP or project tools). Designate a “network manager.” |

The Final Stitch: Weaving It All Together

Building a hyper-local supply chain is more like tending a garden than engineering a machine. It requires patience, nurturing, and a willingness to adapt to the local soil. You’re not just buying parts; you’re investing in relationships and building community capital.

The end result? Honestly, it’s a business that’s harder to break. One that can bend with the winds of global disruption instead of snapping. One that has a story woven into the very fabric of its region. For retail, that means products with a soul on the shelf. For manufacturing, it means a foundation that’s rooted, not floating on the volatile seas of global logistics.

It asks a fundamental question: What if the strongest link in your chain wasn’t a link at all, but the entire network holding hands?